While domestic warehousing and logistics have already been transformed by AGV robots, a Chinese tech company has quietly executed a brilliant “lightning strike” in American warehouses—Mooe’s self-developed unmanned forklift, equipped with the “Mooe Commander” light delivery system, completed the full deployment process in overseas warehouses within just 24 hours, and disrupted traditional warehousing logic with real-time online inventory management. This “efficiency revolution” across the Pacific demonstrates the hardcore strength of Chinese automation technology to the world.

24-Hour “Lightning Deployment”: Solving the Challenges of Overseas Implementation

Traditional automated equipment sent overseas often encounters pain points such as time zone coordination difficulties, slow technical adaptation, and long debugging cycles. However, the Mooe Commander system of the Mooe unmanned forklift rewrites the rules with three major advantages:

Cloud Configuration + Edge Computing: The system pre-sets a multi-scenario algorithm library, eliminating the need for on-site programming; tasks can be issued remotely with a single click.

Adaptive Environmental Perception: With dual insurance from laser radar and visual recognition, it automatically identifies the height of goods and the width of passageways, completing path planning in just 30 minutes.

Modular Hardware Design: Core components support “plug-and-play” functionality, allowing for quick replacements in case of sudden faults, improving operational efficiency by 50%.

From unboxing to full warehouse coordination, the Mooe team completed a week’s worth of work for competitors in just one day, leaving American clients in awe, declaring it “unbelievable.”

Online Management from a “God’s Eye View”: Teaching Warehouses to “Think”

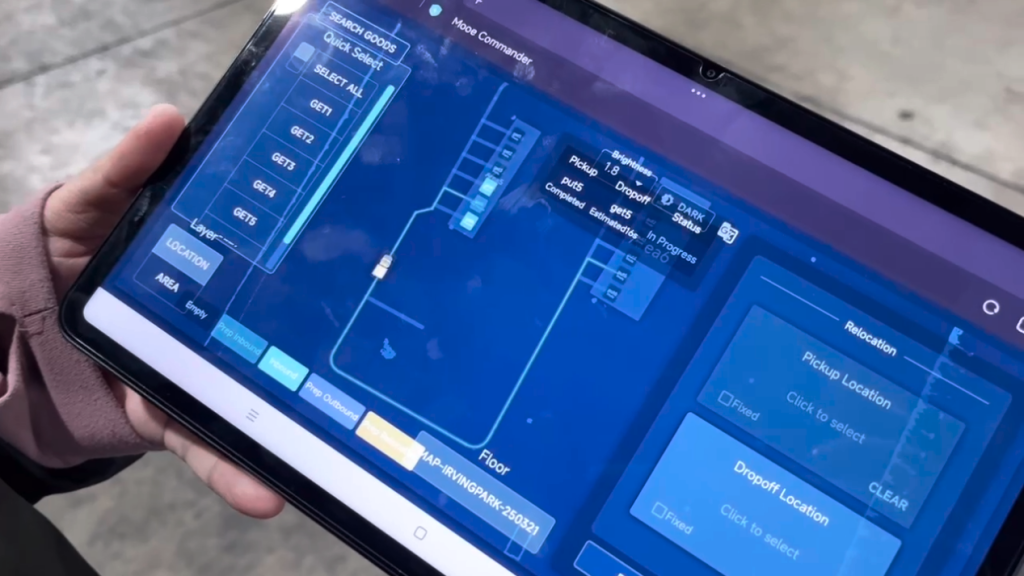

The true revolution lies in the inventory management capability enabled by the Mooe Commander:

Dynamic Inventory Heat Maps: The system tracks the storage density of goods in real time, automatically dispatching forklifts to prioritize the handling of high-frequency products.

Anomaly Prediction and Warning: It anticipates potential risks in goods storage and triggers commands for relocation ahead of time.

Cross-Warehouse Collaboration Optimization: It supports inventory allocation across warehouses, allowing urgent orders to tap into resources from nearby warehouses, enhancing overall turnover efficiency by 40%.

Case Study: After introducing this system, an overseas warehouse in the U.S. saw order processing speed increase by 60% during peak sales periods, while human intervention rates dropped below 5%.

The “China Speed” of Global Expansion: Mooe’s Technological Ambition

From Shanghai to the U.S., the Mooe unmanned forklift has landed in multiple countries worldwide, but the ambition of the Mooe Commander doesn’t stop there:

Lighter: The system supports wireless communication and private deployment, adapting to complex overseas network environments.

Smarter: Integrating digital twin technology allows for remote simulation of warehouse layouts, reducing solution verification cycles by 70%.

More Open: An API interface is provided to support seamless integration with WMS, ERP, and other systems, creating a closed-loop warehousing ecosystem.

In today’s world of explosive cross-border e-commerce and rising labor costs, Mooe’s unmanned forklift redefines the rules of overseas warehousing through technological leaps. This “efficiency revolution,” which began in Shanghai and is sweeping across the globe, allows the global supply chain to hear the “heartbeat” of future warehouses.